For a far more subdued design attempt a nude nail. Bentonite slurry is a combination of sodium bentonite and slurry.

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Cement bentonite mix design You will need a steady hand for this eye catching nail design however its oh-so worth it.

. BENTONITE ADDITIVE TO CEMENT TABLE Percent Bentonite Gallons of water bags of cement Slurry Yield gallons bag Multiply for bags of Bentonite required Multiply for bags of cement required 10 117 1578 0103 56 8 104 1436 0092 61 6 91 1294 0077 68 4 78 1159 0057 76 2 65 1017 0032 87 0 52 882 0000 100. Bentonite can be added to any API class of cement and is commonly used in conjunction with other extenders. The lower the bentonite extended cement slurry density is cement mechanical properties will be poor Table 3-3 and 3-4 taken from Well cementing II edition and The addition of bentonite to a cement slurry requires additional mix water.

This study was undertaken to determine the strength of calcium bentonite as affected by cement and slag. Soil-Cement-Bentonite SCB slurry walls have been used with increasing frequency in recent years to provide barriers to the lateral flow of groundwater in situations where the strength of a normal soil-bentonite wall would be inadequate to carry foundation loads. At the slurry plant cement or some other setting agent is added to the bentonite slurry.

6 rows bentonite powder. The C-B slurry coats the sides of the trench with a thin slippery layer known as a filter cake. Bentonite cement earthfill sand unpermeable layer.

Step one adds the water choosing ratio mass. A slurry is a thin sloppy mud or cement or in extended use any fluid mixture of a pulverized solid with water often used as a convenient way of handling solids in bulk. INTRODUCTION If the natural soil does not meet the requirements of the.

The bentonite slurry was mixed for a period of three minutes. Data are presented from design mix studies and field-testing programs to. The viscosity of the mixed slurry is designed to be in the fluid range during the excavation process.

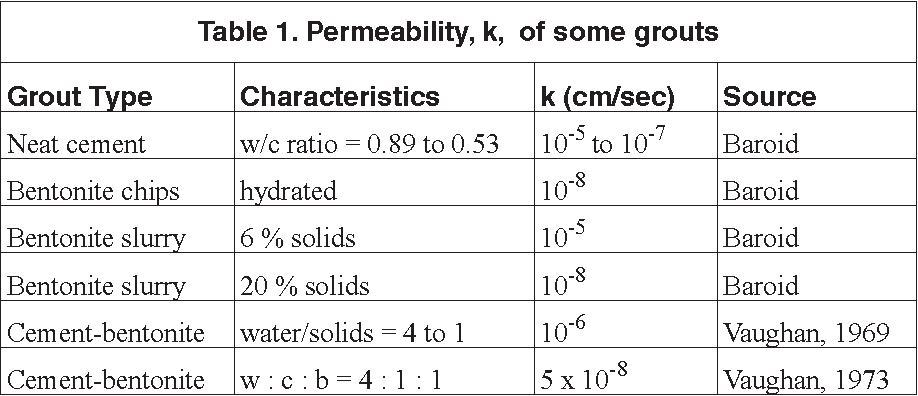

Once the excavation is to full depth the bottom is cleaned and the process moves on. Type I cement is used in neat cement grout and concrete grout mixtures. Neat cement slurry is superior to bentonite as a grouting material in high bedrock situations especially fractured limestone.

If the concentration Cs is expressed as kilograms of bentonite per cubic meter of final slurry then the formula becomes. Soil-Cement-Bentonite SCB slurry walls have been used with increasing frequency in recent years to provide barriers to the lateral flow of groundwater in situations where the strength of a normal soil-bentonite wall would be inadequate to carry foundation loads. 14 rows Cement Slurry design Basics.

The Use of Slag Cement in CB Seepage Cutoff Walls for Levees. Ps pw 1 C CGp 1 where pw is the specific gravity of the mixing water assumed to be 10 and Gp is the grain specific gravity of the bentonite powder used to prepare the slurry. Test specimens were prepared with 15 calcium bentonite 5 to 15 cement and 75 to 10 slag.

The mix resulted in 9 percent cementitious materials a watercementitious material ratio WC of 034 and 09 percent bentonite. Bentonite is used to. A preparation method for cement bentonite slurry body preparation comprises the following steps.

This combination is frequently utilized to form a solid protective barrier in the ground. Bentonite Slurry in civil engineering. Because of the relative simplicity.

A rule of thumb is for each 1 of bentonite an additional 53 of water is required. R an Steven R. It is one of two extenders that are covered by an API specification.

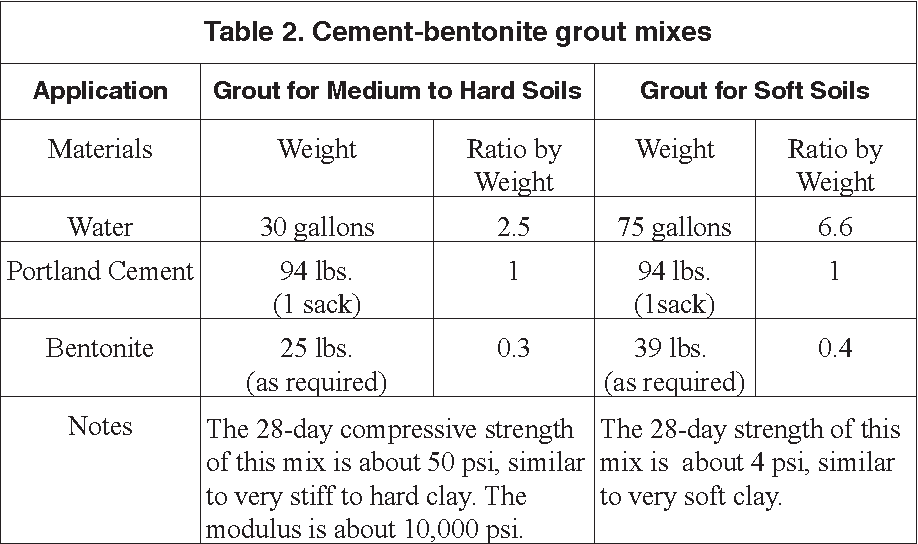

The final mix design consisted of 180 pounds of cement 51 pounds of flyash 2542 pounds of soil dry weight 50 gallons of bentonite slurry and 312 gallons of reservoir water. The addition of cement to the backfill blend allows the backfill to set and form. If you do not have a gradual hand nevertheless there are lots of nail stickers stamps or head on to your neighborhood nail salon so they can replicate it for you.

CEMENT-BENTONITE SLURRY WALL MIX DESIGN Christopher R. The bentonite slurry was mixed in a Hobart mixer. Cement Bentonite Mix Design.

First here is a handy table to simplify the process of cement. The C-B slurry is prepared by combining cement with a hydrated bentonite-water mixture just before discharge of the C-B slurry into the trench. The mixture including 10 bentonite 90 sand is the most economical solution that satisfies the limits values needed for clay core of earth fill dams and clay liners of solid waste storage areas.

It forms a hard rock-like seal around the casing which will not wash out from ground water flow in the formation. Download scientific diagram Design Proportions for SCCB Mix Design Program from publication. This minimizes the slurry seepage out of the trench and groundwater seepage into the trench.

Source water was poured into the mixer and the mixing blade was turned on then bentonite was added. Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. CB Design Mix At least two weeks prior to construction the Contractor shall submit proportions and properties of the proposed CB design mix including cement bentonite additives and water proportions.

Viscosity density Unconfined Compressive Strength and permeability to the Owners Representative for review and approval. Bentonite is typically used at concentrations of 1 to 16 BWOC. The slurry is then pumped from the mix plant to the excavation.

Using bentonite slurry as a permanent filling material ACtrafficengr CivilEnvironmental 1 Jun 11 0836 Usually a cement grout is used for a structural reinforcement or controlled low strength material aka flowable fill if its just filling space. The two common types of slurry walls are soil bentonite SB and cement bentonite CB walls. Day ÄBSTRÄCT Ä cementbentonite CB slurry cutoff wall is a variation of the slurry wall process that is used to create an underground barrier to stop the lateral flow of ground water and other fluids.

Mix Design Rules In order to keep field procedures simple the emphasis. Tolunay-Wong hydrated the bentonite slurry for 4 hours prior to adding it to the soil or to the soil and dry bentonite mixtures.

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Cement Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved

Soil Cement Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

Design Proportions For Sccb Mix Design Program Download Scientific Diagram

Concrete Mix Design Used For Laboratory Tests Download Table

Blend Mix Proportions And Blend Slurry Properties Download Table

0 comments

Post a Comment